Fry’s Metal Foundries Ltd was at the Tandem Works in Christchurch Road from 1930 to 1991.

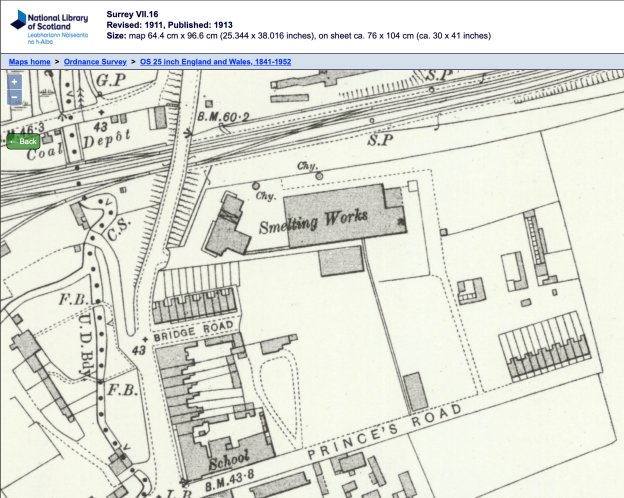

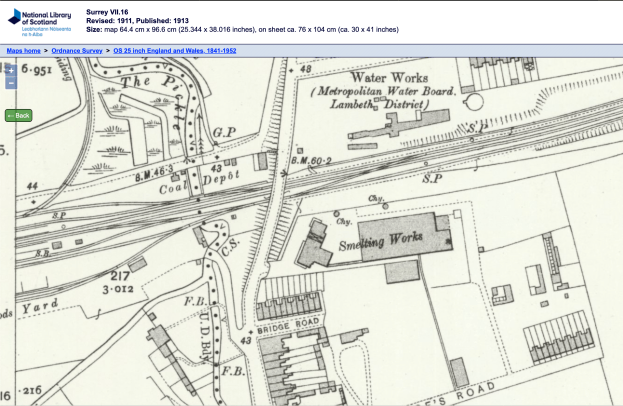

The smelting works shown in this 1911 OS map had been built in 1907 by the German-owned Tandem Smelting Syndicate and was so named as the business worked in tandem with its counterpart in Germany.

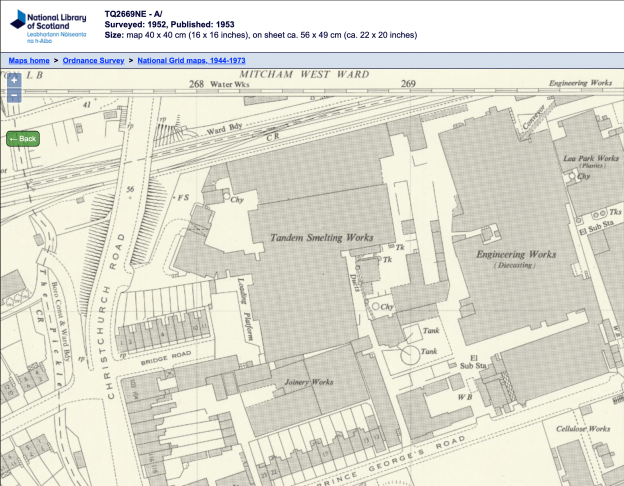

This 1952 OS map how the premises had expanded, with the diecasting works to the east of the smelting works.

Timeline of Events

1806: George Hallett & Co., an antimony-smelting business, is founded south of the Thames.

1841-1861: George Hallett & Co. operates at 52 Broadwall, Blackfriars.

1891: Herbert Frederick Höveler arrives in Britain from Germany, bringing with him advanced metal scrap and residue treatment expertise.

1894: Höveler forms the Tandem Smelting Syndicate Ltd.

1902: The Eyre Smelting Company is established in Tonbridge.

1904-1908: The Rotherhithe Tunnel is constructed beneath the Hallett & Fry factory.

1906: Höveler begins building the Tandem Works in Mitcham.

1907: The Tandem Works opens.

1908: John Fry rejoins Hallett & Fry after serving in the South African War.

1911: John Fry begins attending evening classes in metallurgy and chemistry at the Northampton Institute.

1912: John Fry leaves Hallett & Fry.

1913: Fry’s Metal Foundry expands, adding No. 30 Holland Street.

1914: Fry’s Metal Foundry expands, adding No. 29 Holland Street.

1915: Fry’s Metal Foundry expands, adding No. 26 Holland Street.

1916: Fry’s Metal Foundry opens its first branch foundry in Manchester.

1917: The Eyre Smelting Co. Ltd begins producing munitions in Tonbridge.

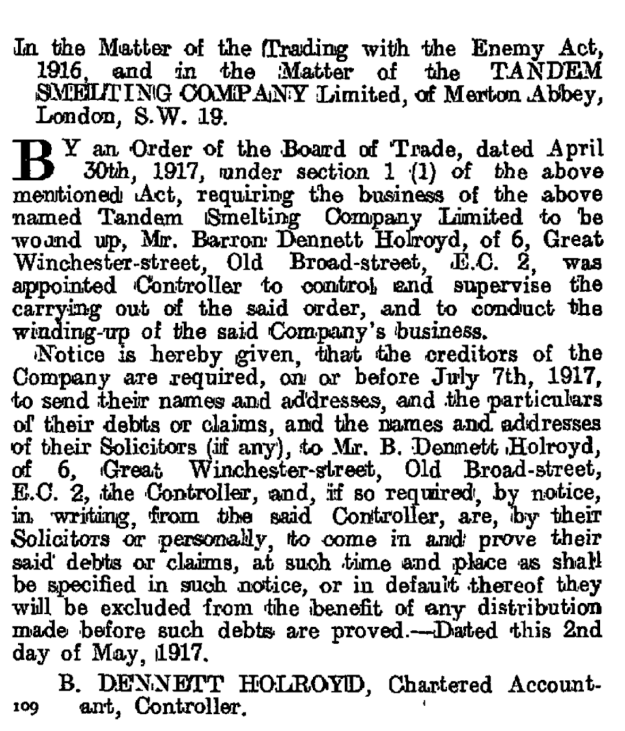

1917: Tandem Smelting Co. wound up under the Trading with the Enemy Act, and the site sold at auction, and bought by the Eyre Smelting Co.

1918: The Tonbridge Eyre Smelting Works is sold, and operations are transferred to the Tandem Works.

1919: The new block at 42 Holland Street is completed, featuring a laboratory.

1920-1930: Fry’s Metal Foundry opens an iron foundry at Hillside, Kingsbury. Fry’s Metal Foundry begins diecasting operations. Fry’s Metal Foundry opens a foundry in Scotland.

1923: Eyre Francis levers visits Fry’s Metal Foundry in Holland Street.

1925: Fry’s Metal Foundry becomes a limited liability company, Fry’s Metal Foundries Ltd.

1926-1930: Fry’s Metal Foundries Ltd gradually transfers operations from Holland Street to the Tandem Works.

1927: Fry’s acquires the British Empire rights to Josef Polak’s hydraulic pressure diecasting machine patent.

1928: Part of Fry’s foundry and the entire laboratory are transferred to the Tandem Works.

1931: The Indian Metals & Alloys Co. Ltd (IMAC) is formed in Calcutta.

1932: The decision is made to separate the diecasting side of the business.

1933: Fry’s Diecastings Ltd is formed and opens a factory in Prince George’s Road.

1934: The solder department becomes a separate unit at the Tandem Works.

1935: Soldering flux manufacture is introduced.

1936: A separate factory for fluxes is established, as is the research department.

1939: The Tandem News, a monthly leaflet, is first issued. World War Two begins.

1944: Fry’s Metal Foundries Ltd joins the Goodlass Wall Group. Operations commence at the Willow Lane site under the name of Eyre Smelting Co. Ltd.

1946: Fry’s Diecastings Ltd joins the Goodlass Wall Group.

1947: Fry’s and H.J. Enthoven form Enthoven Fry Ltd to manufacture lead and tin alloys in South Africa.

1948: Enthoven Fry Ltd begins operations in Germiston, South Africa.

1950: A fire erupts at the Willow Lane site.

1951: Fry’s Diecastings Ltd opens a foundry on the Bede Estate near Newcastle upon Tyne.

1953: Enthoven Fry Ltd opens a second factory in Port Elizabeth, South Africa.

1956: Fry’s Metals Ltd invents the “Flowsolder” process for soldering components to printed circuit boards.

1957: Fry’s Diecastings Ltd opens a northern works on the Bede Estate.

1958: Fry’s opens a branch in Madras, India. The Glasgow branch moves to a new building in London Road. The Kidderminster branch opens.

1960: The Eyre Smelting Private Ltd in Calcutta moves to Behala.

1961: The “Flowsolder” division moves to Willow Lane.

1962: Chill-cast bronze and gunmetal rod production transfers from the Tandem Works to Willow Lane.

1963: The Eyre Smelting Private Ltd in Calcutta opens a small office in New Delhi.

1965: Solder wire manufacture commences at Willow Lane.

1967: Fry’s Metal Foundries Ltd changes its name to Fry’s Metals Ltd. The Eyre Smelting Co. Ltd, The Atlas Metal & Alloys Co. Ltd, and Fluxite Ltd cease as separate trading companies and become divisions of Fry’s Metals Ltd. John Fry passes away.

1968: Work commences on a new building at Willow Lane to house solder wire and silver solder production.

1969: Fry’s acquires Castle Metals in Cape Town, South Africa.

1971: The “Bone Works” in Manchester is acquired by Fry’s. Nancy Louise Fry passes away.

1980: A flux factory is added to the Kidderminster branch. Eyre Smelting of India drops the word ‘Private’ from its name.

1982: All operations in Manchester are transferred to Rochdale.

1984: Alpha Metals Ltd moves from Ewell to Tolworth, and the Willow Lane site is sold.

1986: Fry’s Metals ceases smelting operations at the Tandem Works.

1989: Eyre Smelting Ltd of Calcutta, Madras, and New Delhi changes its name to Cookson India Ltd.

1991: Fry’s Metals moves from the Tandem Works to Tandem House in Croydon. Fry’s Metals is fined for polluting a waterway with copper sulphate pickling liquor.

1994: Alpha and Fry’s amalgamate, becoming Alpha-Fry Ltd.

2000: The Glasgow branch closes its London Road foundry.

2002: The Marlowe Way site in Croydon closes.

2004: The Rochdale foundry closes.

Cast of Characters

Herbert Frederick Höveler (1859-1918): A German industrial chemist and metallurgist who founded the Tandem Smelting Syndicate Ltd. He was an inventive individual with interests beyond metallurgy, including Esperanto and asthma cures.

John Horace Fry (1876-1967): The founder of Fry’s Metal Foundry and a pioneer in the scientific development and application of printing metals. He was dedicated to providing service and quality to his customers and was a generous supporter of trade charities.

Nancy Louise Fry (1881-1971): John Fry’s wife, who played a key role in the early success of Fry’s Metal Foundry, managing the finances and providing moral support.

Alfred H. Mundey (1868-1951): A chemist and metallurgist who was John Fry’s mentor and the first consultant metallurgist for Fry’s Metal Foundry. He played a crucial role in educating the printing trade about printing metals.

Roger Bowbrick (1887-1978): A foundry manager for Fry’s Metal Foundry, who was instrumental in the development and refinement of the company’s metal production processes.

Eyre Francis Ievers (1870-1945): A key figure in the Eyre Smelting Co. Ltd and later a member of the Fry’s Metal Foundries Ltd board. He facilitated the eventual amalgamation of the two companies.

Sir William Treloar (1843-1923): A former Lord Mayor of London who owned the Holland Street premises where Fry’s Metal Foundry was established. He offered John Fry a lease on the property, enabling the company to launch.

P.M. Parish: An early employee of Fry’s Metal Foundry who later became chairman of the company.

G.W. Gibson: An early employee of Fry’s Metal Foundry who later became managing director of the company.

Alexander Miller-Hallett (1870-1953): John Fry’s business partner at Hallett & Fry. His unwillingness to share ownership of the business led to John Fry’s departure and the founding of Fry’s Metal Foundry.

George Miller-Hallett: Alexander Miller-Hallett’s eldest son, who joined Hallett & Fry in 1906. Despite the business tensions between their fathers, he remained a good friend of John Fry.

Thomas Henry Fry (1845-1920): John Fry’s father and a partner in Hallett & Fry. He played a key role in reorganizing and establishing the financial stability of the antimony-smelting business.

Arthur Street: A driving force behind the development and expansion of Fry’s Diecastings Ltd, particularly in the adoption of new diecasting technologies.

John Holt: Instrumental in developing bismuth refining and the manufacture of indium trichloride at the Glasgow branch of Fry’s Metals. He also played a role in adapting fusible alloys for use in complex plastic injection moulding.

Frank Todd: A pioneer in promoting the use of fusible alloys for making complex plastic injection mouldings at the Glasgow branch.

Charles Langford: Manager of the Indian Metals & Alloys Co. Ltd (IMAC), succeeding Stanley Brown.

W.J. Woodhouse: A decorated Air Force officer who joined IMAC and eventually took over its leadership.

Listed in the 1963 Borough of Mitcham List of Factories as

Bridge Road, SW19

Flux Manufacturers

Prince Georges Road

Metal Work

Rear of 24 Willow Lane

Leadstrip and Casting

Aerial views of the Tandem Works can be seen in this video: